Home

About

MODBUS

About

Enron

MODBUS

RTU Master

RTU Slave

manual2

manual7

manual8

TCP Client

Download

Purchase

Contact

Operation Manual

Simply Modbus Slave 8

Modbus RTU Slave and Modbus ASCII Slave Software

System Requirements:

Windows NT, 95, 2000, XP, Windows7, Windows8

display resolution: 800 x 600 minimum

PC with serial port (built in, serial card or USB serial port)

Installation - Simply Modbus Slave 8.1.3:

SimplyModbusSlave8.1.3Install.zip

118 MB - click to download

Unzip the compressed files into a common folder on your hard drive.

setup.exe

- the install program

setup.ini

nidist.id

End User License Agreement.pdf

license (folder)

bin (folder)

supportfiles (folder)

- Run setup.exe to start the Simply Modbus Slave 8 Installation Wizard

- Follow the prompts. The program will start automatically when the

installation is complete.

Starting the program

Select Simply Modbus Slave 8 from the Program area of the Start Menu.

You will see the demonstration startup window.

The progress bar will take approximately 15 seconds to load the demonstration version.

During this time, you can press the ENTER KEY and see

After purchasing and receiving a license key by email, enter the key and press OK.

The licensed program

- goes immediately to the main Simply Modbus Read window and bypasses the demonstration startup window.

- allows unlimited reads and writes.

The demo version

- offers full functionality

- requires a program restart to send more than six replies to requests.

The Simply Modbus Slave Window

Yellow: Controls (inputs) that can be changed by the user.

Blue: Indicators (outputs) that cannot be directly changed.

Program Summary:

When the program is opened, the circular clock indicator spins to show that the program is running. The program monitors the chosen serial port looking for incoming bytes from a modbus master. All bytes received (and sent) are displayed in the 'Log'.

The most recent request received is displayed in the indicator labelled "Latest Request received". A lookup is done to determine if the request has a valid SlaveID, function code, data addresses, valid data if writing and valid error detection bytes (CRC or LRC.

The request must meet the following 2 conditions before a response is generated and sent:

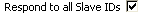

1) The ID in the request (the first byte received) must match the entered Slave ID,

or 'Respond to all Slave IDs' must be checked.

If the ID does not match, the Slave program will ignore the request since it is intended for a different slave.

2) The CRC (if RTU mode) or LRC (if ASCII mode) at the end of the request must be correct.

The request must meet the following additional conditions before a response with data is generated and sent:

3) the request must have a function code that matches enabled data in the tables.

Function code 03 or 04 to read registers with a block of register data set with the same code.

Function code 06 or 16 to write registers with a block of register data set as read/write.

Function code 01 or 02 to read coils with a block of coil data set with the same code.

Function code 05 or 15 to write coils with a block of coil data set as read/write.

If not, an exception code 01 is generated and sent.

4) The requested registers or coils must exist in an enabled block. More

specifically, the request must be for register

or coil addresses with a hex values that match the register number minus

offset for one of the enabled tables.

If not, an exception code 02 is generated and sent.

For example, A request for 0003 addresses starting from 0002 will match

a block setup with Registers 40001 to

40008 and offset 40001. It will reply with data from 40003, 40004 &

40005. A request for 0007 addresses

starting from 0002 will not match the same block, since it needs

registers 40003 through 40009.

Since 40009 does not exist in the block, an exception code 02 would be

generated and sent.

5) When receiving function codes that request writing data, the data

size and format must be correct.

If not, an exception code 03 is generated and sent.

For example, A FC16 request to write 0005 16bit addresses must contain 10 data bytes (two bytes per address),

otherwise an exception code 03 would be generated and sent.

When a response is generated, it is written to the serial port and the Log.

On a multi-dropped network (eg. RS485) with multiple slaves, this application will also receive responses from other slaves.

All messages received will be monitored and processed to determine if they are valid requests from a modbus master.

Setup Details:

Enter the input information in the controls to match the Slave you wish to emulate.

Select RTU or ASCII mode. more info...

Select RTU or ASCII mode. more info...

Select the serial port on your PC that is connected to a modbus master.

The COM port will show red shading when a non-existent port or one with errors is selected.

Range = COM1 to COM99

serial settings: Set these settings to match the setting of the modbus slave device connected.

baud: The baud rate (bits per second) of the serial connection.

data bits: The number of data bits in each byte, RTU mode requires 8, ASCII mode is usually 7 but may be 8.

stop bits: The number of stop bits for each byte sent. allowable values are 1, 1.5 or 2 .

parity: The value of the parity bit for each byte sent. allowable values are none, odd, even, mark or space.

The 1st byte in the Request and Response strings

The unit address of the Slave device to be emulated. normal range: 1 to 247

The program will only respond to requests directed to this Slave ID.

When this box is checked, the program will respond to requests directed to any Slave ID.

When this box is checked, the program will respond to requests directed to any Slave ID.

Other Settings:

When checked, the program will send the data high byte first

When checked, the program will send the data high word first for 32 bit data types.

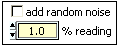

When checked, the program will apply a

random multiplier to the values found in the tables

to a maximum of the '%reading' value entered.

The program will then give slightly different responses when the same

request is repeated.

![]()

Context help is available by pressing

Ctrl-H while in the program.

Information is displayed about items as the cursor hovers over them.

For example...

Byte History Log

All bytes sent and received are added to the byte history log with date/time stamps.

Displays a 'Save As..' dialog box to allow the log contents to be saved to a text file.

Empties the log contents.

![]() Uncheck this box to keep the log from scrolling when new data is added.

Uncheck this box to keep the log from scrolling when new data is added.

![]() Displays information about the program including the program version.

Displays information about the program including the program version.

Press the Close box 'X' in the top corner to Exit the program.

Data Table Setup Details:

Press the

![]() button to display and change the register and coil

tables.

button to display and change the register and coil

tables.

Six data tables can be setup that contain the blocks of data for the slave to respond with.

Blocks 1 to 4 are registers for storing numerical data

Blocks 5 to 6 are coils for storing boolean (on/off) data

![]() Each block can be set to enabled or disabled.

Each block can be set to enabled or disabled.

![]() Each register block is set to respond to either FC03 or FC04 read register requests.

Each register block is set to respond to either FC03 or FC04 read register requests.

Each coil block is set to respond to either FC01 or FC02 read coil requests.

![]() Each block can be set as read only to accept the only the function code above,

Each block can be set as read only to accept the only the function code above,

or read/write to allow the host to change the data with FC06&16 (for

registers) and FC05&15 (for coils)

![]() Each register block can be set as 16bit registers (typical for standard modbus),

Each register block can be set as 16bit registers (typical for standard modbus),

or 32bit registers (used for Enron modbus 32bit Int (5000) block or 32bit float (7000) block)

This control selects the data type for the table. more info...

All values in one table have the same data type.

Selectable as 16bit Unsigned Integer (0 to 65535)

32bit Unsigned Integer (0 to 4.3 billion)

16bit Signed Integer (-32768 to 32767)

32bit Signed Integer (-2.1 to 2.1 billion)

32bit IEEE Floating Point

Selecting a 32bit Data type with 16 bit register size will use 2 registers for each value.

![]() Sets the register or coil numbers for the block.

Sets the register or coil numbers for the block.

![]() Sets the difference between the register number and the hex number used in the commands for each block.

Sets the difference between the register number and the hex number used in the commands for each block.

For example register#40005 minus offset 40001 = hex address 0004)

![]() This sets how many registers or coils are in each block.

This sets how many registers or coils are in each block.

A read-only indicator displaying the register or coil numbers as set above.

A read-only indicator displaying the hexadecimal equivalent of register or coil numbers minus the offset.

This is where the data values are entered.

![]() Press OK to accept the changes entered.

Press OK to accept the changes entered.

![]() Press CANCEL to leave the data unchanged.

Press CANCEL to leave the data unchanged.

Save and Restore Configurations

Displays a 'Save As..' dialog box to allow saving the current settings to a text file.

Displays a 'Save As..' dialog box to allow saving the current settings to a text file.

The data file is saved in csv format (comma separated values).

The file can be edited with a spreadsheet application and reloaded into the program using RESTORE CFG

Displays a 'Open File' dialog box to allow selecting a previously saved settings file to load.

Displays a 'Open File' dialog box to allow selecting a previously saved settings file to load.

The configuration file is saved in tabbed text format (tab separated values) and appears like this in notepad...

The preset tabs in Notepad cause the cells with long

labels to push the other columns over.

Sending it to, or opening it

from, a spreadsheet program like Excel will use the tabs as column delimiters

as shown here...

Columns A & B contain the setting descriptions and their values.

Mode 0 = ASCII, 1 = RTU

serial port 1 = COM1, 2 = COM2 etc

baud rate

data bits

stop bits 0 = 1bit, 1 = 1.5bits, 2 = 2bits

parity 0 = none , 1 = odd, 2 = even, 3 = mark, 4 = space

slave ID

byte order 0 = low byte first, 1 = high byte first

word order 0 = low word first, 1 = high word first

add noise 0 = unchecked, 1 = checked

%reading Integer 0 to 100

scroll lock 0 = unchecked, 1 = checked (lock scrollbar at bottom)

The remaining columns contains the data from the 6 data tables:

enabled 0 = disabled, 1 = enabled

function code 0 = FC 03, 1 = FC 04 (for the 4 register tables)

function code 0 = FC 01, 1 = FC 02 (for the 2 coil tables)

read/write 0 = read only, 1 = read/write

register size 0 = 16 bit, 1 = 32 bit (not applicable to coil tables)

data type 0 = 32bit IEEE Floating Point (0 = 1 bit for coil tables)

1 = 32bit Unsigned Integer (0 to 4.3 billion)

2 = 32bit Signed Integer (-2.1 to 2.1 billion)

3 = 16bit Unsigned Integer (0 to 65535)

4 = 16bit Signed Integer (-32768 to 32767)

1st Register : the register number of the first

register including the offset

Offset : The offset between the register numbers

and their hex values for the table

Number of values: The size of the table

The table settings are followed by the register or coil numbers and

their corresponding values.

The data can be saved and edited within a spreadsheet and then loaded into the program with the RESTORE CFG button.

Physical Connection:

To receive requests from a modbus master before sending a message, the serial port needs to be physically connected to a modbus master device. The simplest connection is RS232C on a single serial cable.

DTE masters (PC serial ports) have DB9 male connectors which transmits on pin3, receives pin2 and grounds on pin5. A DCE slave will have a DB9 Female connector which will allow the use of a straight through cable. A DTE slave will have a DB9 Male connector and will require the use of a null modem cable.

The RS232 specification states a maximum distance of 50 feet at 20kbaud. Slightly longer connections are possible at slower baud rates depending on cable quality and noise in the area.

Modems and radios are used to transmit longer distances. These are typically DCE devices so straight through cables can be used. Some MDS non-spread spectrum radios require RTS Delay to be used so a 4th conductor is needed on pin 4.

RS485 converters can be used to extend the distance up to 4000 feet at 100kbaud. This can be a 4 wire or 2 wire system, depending on the converter. This also allows multi-dropping up to 32 devices on one pair of wires.

Program Operation:

Once the correct input data is entered, the program operates by itself.

When bytes are read on the serial port, they are displayed here.

The bytes are then processed to see if a response should be generated.

![]()

The first byte of the request is shown in 'ID'. This is the Slave Address that the Master is requesting a response from.

This hex value is converted to decimal and compared to the 'Slave ID' entered.

If they match or if "Respond to all Slave IDs" is selected, the 'ID match' indicator will turn green as shown.

![]()

The second byte of the request is shown in 'fc'. This is the Function code indicating which table to read from.

This program support function codes 01,02,03,04,05,06,15 (0F hex) and 16 (10 hex).

If one of these function codes is found in the request, the 'fc okay' indicator will turn green as shown.

The 3rd and 4th bytes of the request are shown in '1st register req'. This is the register address of first register to read.

This number is converted from hex to decimal and shown in 'First Register

req'.

The program then looks for this register in the data tables showing the

function code above.

If found, the matching table is displayed in 'found in block', and the

'data found' indicator will turn green as shown.

The 5th and 6th bytes of the request are shown in 'number of regs'. This is the number of registers to read.

This hex value is converted to decimal and displayed in '# of Registers'.

![]()

The 7th and 8th bytes of the request are shown in 'CRC' (or 'LRC' if in ASCII mode).

The expected CRC (or LRC) is calculated from the first 6 bytes and

displayed in 'Expected CRC' (or 'Expected LRC').

If the two match, the 'crc ok' indicator will turn green as shown.

crc The last 2 bytes of a modbus RTU message are the cyclic redundancy check. These are error detection bytes more info...

lrc ASCII Mode messages are preceded with a colon and the crc is replaced with an lrc (longitudinal redundancy check), carriage return and line feed characters. more info...

If the 'ID match', 'fc okay', 'data found' and ' crc ok' indicators

all turn green, a response with data will be generated.

The data is read from the matching table and a response is generated and

returned.

A breakdown of the response is shown in the registers table

A breakdown of the response is shown in this table. A scrollbar

will appear for responses with more than 5 values as shown here.

The columns show the register number (including the offset), its value in hex,

the decimal value of the data and this value in hex.

The response string is generated from the data

and shown in 'Latest Response given'.

This is an example of a response with 6 data bytes.

The bytes in the above data response are explained here:

0A The Slave ID responding

03 The function code

06 The number of data bytes to follow

00 1E 00 28 00 32 00 46 00 50 The data bytes representing the values in the requested registers.

E4 71 The CRC (or 'LRC' if in ASCII mode).

If the 'ID match' and ' crc ok' indicators both turn green, but the function code found is not supported, a response is generated with exception code '01'.

If the 'ID match' and ' crc ok' indicators both turn green, but the data is not found in the table, a response is generated with exception code '02'.

If the 'ID match' and ' crc ok' indicators both turn green, and a 'write data' function code 05, 06, 15, or 16 is found followed by valid data, the data is written to the tables and an appropriate response is generated.

If the 'ID match' and ' crc ok' indicators both turn green, and a 'write data' function code 05, 06, 15, or 16 is found followed by invalid or missing data, a response is generated with exception code '03'.

Troubleshooting

Check the physical connection to make sure the correct conductors are on the correct pins and the correct serial port.

Check the serial settings in the master device to make sure they match the settings in the slave.

Home • FAQ • Enron • Download • Purchase • Contact

Copyright © 2020 Simply Modbus. All rights reserved